- Products

- Industrial Products

- Bolted Coupler & Adaptor Range

- Full Bolted Coupler & Adaptor Range

- 300/425 Amp Series B (Bronze)

- 300/425 Amp Series C (Stainless Steel)

- 300/425 Amp Series C (Aluminium)

- 800 Amp Series D (Bronze)

- 800 Amp Series D (Aluminium)

- Bolted Coupler & Adaptor Accessories

- N Series Glands (To suit Aluminium Series C Couplers)

- No.2 to No.5 Glands (To suit Series B, C & D Couplers)

- Restrained Plugs & Receptacles

- Surefit Cable Glands

- Armoured Glands

- Armoured/Braided Glands

- Blanking Plugs

- Nylon Unarmoured Glands

- Reducers

- Stainless Steel Unarmoured Glands

- Stainless Steel Unarmoured Extended Tail Glands

- Surefit Gland Accessories

- Unarmoured Extended Tail Glands

- Unarmoured Glands

- Weatherproof IP68 Armoured/Braided Glands

- Weatherproof IP68 Unarmoured Glands

- Ellis Cable Cleats

- Bolted Coupler & Adaptor Range

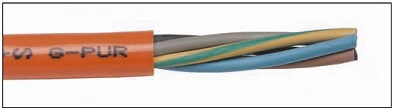

- Electrical Cables

- Industrial Products

- Projects

- Support

- Company

- Contact